It is the “core” of the plant.

Herein we provide for the activated sludge process, through which organic and inorganic suspended solids and part of the dissolved solids achieve the capability of settling.

The principle is based on the utilisation of aerobic bacteria colonies, naturally present in wastewater; these bacteria have three fundamental characteristics:

- they accomplish their vital cycle metabolising the organic matter

- they reproduce increasing quickly.

- they tend to live in and to form colonies

To assimilate and to transform organic matter, the bacteria need oxygen as support of combustion. The final products of this process are H2O, CO2 and new living substance.

The oxygen source will be, partly, the one existing in the water and, partly, that supplied from outside. In this way the natural bio-degradation process accelerates: it should have otherwise taken a longer and thus unacceptable time. The oxygen feed causes a very fast multiplication of the bacteria, they get together in colonies and aggregate in “flakes”.

In these flakes, protoplasm cells, coming from organic synthesis, organic metabolised solids and residual organic matter of vital bacteria cycle, are concentrated. Moreover, organic and inorganic non separable solids adhere to the flakes by adsorption.

Sludge flakes have two characteristics:

- they settle by gravity

- they have high concentration of active organic matter, wherefrom the term of “activated” sludge flakes.

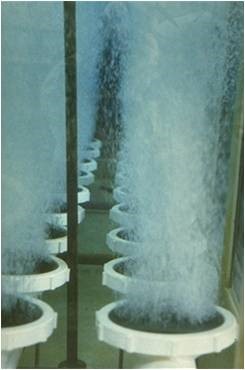

The wastewater is fed with air through an aeration system consisting of:

- fine bubble membrane disc diffusers, with related headers, manifolds and accessories, placed on the bottom of the tank and producing fine bubbles (about 1.5 mm of diameter)

- air compressor station with superchargers or centrifugal blowers.

This is the most efficient aeration system under oxygen transfer point of view, performing the highest energy savings. As in the oxidation stage the energy consumption is equal to 50-60 %, or more, of the total energy consumption, the aforesaid system is very important in the economy of the whole plant. Moreover no aerosol is produced, high flexibility is ensured and, in winter, the warm (50-60° C) incoming air assures an average temperature of the water, which is sufficient and necessary for the process.

An oxygen meter provides for the monitoring of the O2 concentration in the water. The air flow is increased or reduced by a signal (4-20 mA) which “informs” the blower station. This happens by means of a converter or a mechanical flow adjustment system.