The aim of MBR system is to replace sedimentation step in depuration process with a filtration stage. In this way, the separation of sludge from water allows to completely remove any dragging of suspended solids.

Advantages of this technical solution are easy to find: it permits to treat greater wastewater flows in a lower space, allows an easier control of a constant flow and also a more effective treatment.

There are mainly two types of MBR:

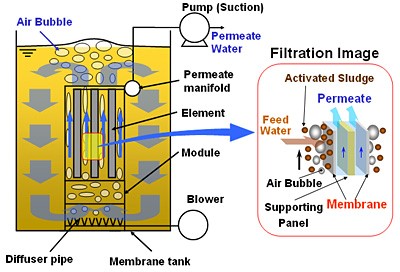

- the most used is the MBR-side stream plant, which consists in an ultrafiltration module sited outside of biological tank;

- as an alternative, is the MBR-submerged membrane plant, where membranes are submerged in oxidation tank and permeate is pumped through them.

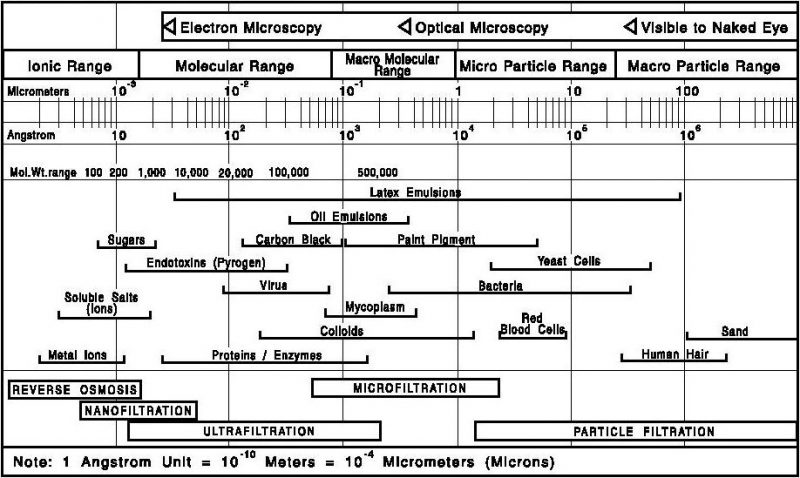

Ultrafiltration or microfiltration allows effective separation of microorganisms and suspended solids not easy to settle, so, sited after a biological degradation treatment of organic pollutants, assure a constant quality of outcoming water.

Substitution of sedimentation step with a membrane filtration stage entails important consequences:

- complete removal of suspended solids and increase of concentration of activated sludge; in this way we obtain greater consumption of incoming BOD5 (and so greater incoming wastewater possible flows with the same depuration efficiency), longer age of sludge, greatly reduction of excess sludge.

- better and constant quality of treated water; with MBR technology we can totally remove any bulking phenomena in clarification stage and we can completely recover treated water in factory services (boilers for example) or internal usages, with further decrease of process costs.

- really compact treatment units, allowing so future expansions of the plant, lower environmental impact, lower maintenance costs, more available space for other usages.

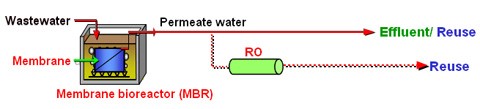

From a constructive point of view, the MBR replaces the clarifier, reducing thereby the area required for the sedimentation of the biomass. From the qualitative point of view, the output water after MBR is quite similar to the one produced with ultrafiltration systems, having values of SDI less than 5 and with molecular size of about 0.05 micron, which makes it suitable for the feeding of RO membranes.

Same characteristics are obtained with the traditional system, using in series a clarifier, followed by a quartz filter and by an ultrafiltration plant. To obtain an optimal functioning of the MBR, it is very important to pay attention on working parameters of the biological plant. In fact, working in the biological process with a too high F/M ratio, may vary biomass characteristics and, therefore, reduce the specific flow of membranes, thus reducing their efficiency and capacity. The recirculation of the sludge separated in the MBR tank follows the same rules of the classic one, made with a traditional clarifier.