Ultrafiltration plant is made of capillary membranes for the treatment of water coming from the biological process.

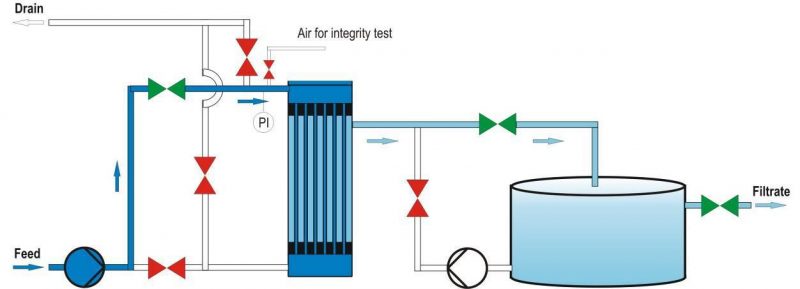

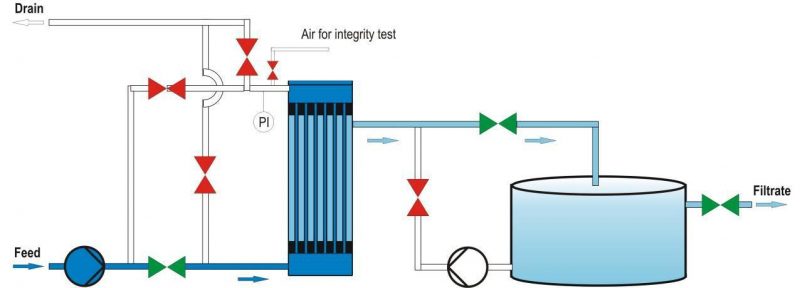

The process of the ultra-filtration unit is divided in different operating modes. These are defined by a specific valve status. A defined sequence of different operating modes is characterized as filtration cycle. After a specified number of filtration cycles, a chemical enhanced backwash occurs.

Depending on different conditions, it can be advantageous to conduct the chemical enhanced backwash with two different chemicals.

Thereby, an optimum adaptation of the plant operation to the water quality is provided.

The operating modes are defined by specific valve status (open/close) and pump status.

During the operating mode “Filtration” the principal filtration occurs. The water is pressed from the feed side through the membrane capillaries to the filtrate side. The backwashing of the membrane is called “Backwash”. In contrast to the “Filtration”, clean water is pressed from the filtrate side through the membrane to feed side into the drain.

The plant is completely automatic, pre-assembled on an AISI 304 stainless steel skid and it is controlled by a PLC unit equipped with operator interface.